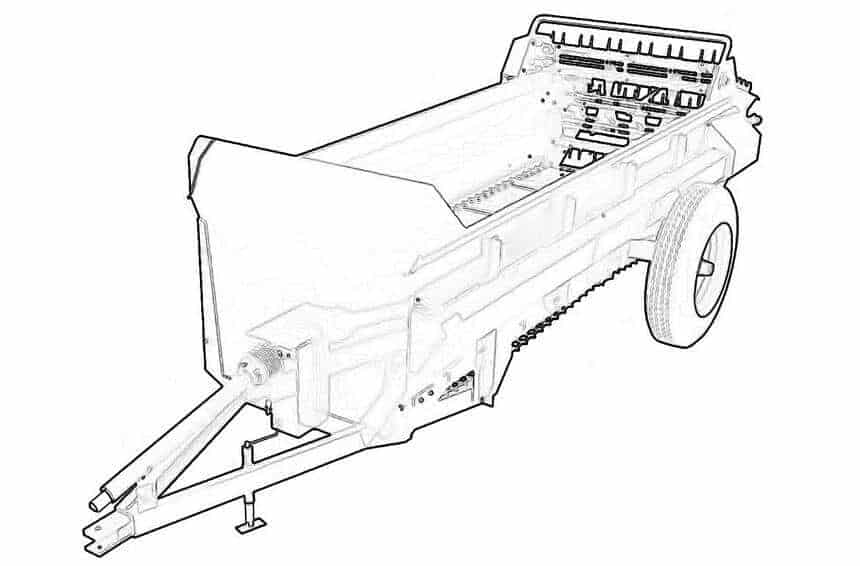

Built in Lancaster Pennsylvania, by highly skilled craftsman with decades of spreader building experience, these spreaders are crafted for daily farm-use-conditions and made of the most durable components we know of. Materials such as grade-5 bolts, greaseable bearings, oil-impregnated bronze bushings, heavy-duty size 60 roller chain (nearly 1″ wide), T-Rod apron chain, and hardened sprockets ensure longevity. You can judge a spreaders materials and components quality by its overall unit weight, the heavier the better. The ABI spreader weighs nearly 1/3 more than equivalently sized competitors spreaders. Now that is tangible quality you can feel!

4-Speed Variable Flow Control

Unlike most competitors, all ABI Classic Manure spreaders feature the ability to control the flow rate of manure being applied to the ground with 4 different speeds. Flow control is accomplished by speeding up or slowing down the apron web, that feeds manure to the back beaters, independently of ground speed. The speeds are adjusted via the front lever and enables the operator to either empty the manure as fast as possible or apply controlled amounts of manure to specific areas to maximize its’ fertilizer value. Variable flow control also enables this spreader to handle a wider range of manure, as manure consistency can change depending on manure type, bedding material, stage of decomposition, and weather, without causing damage or additional maintenance to the spreader. And finally having 4-speeds encourage an eco-balanced pasture by enabling a slow manure feed rate and high beater spin rate for fine shredding and spreading.

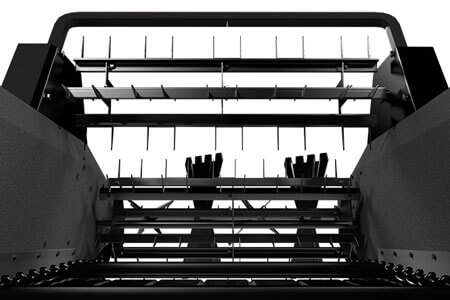

Shreds & Then Spreads - 3 Beater Bars

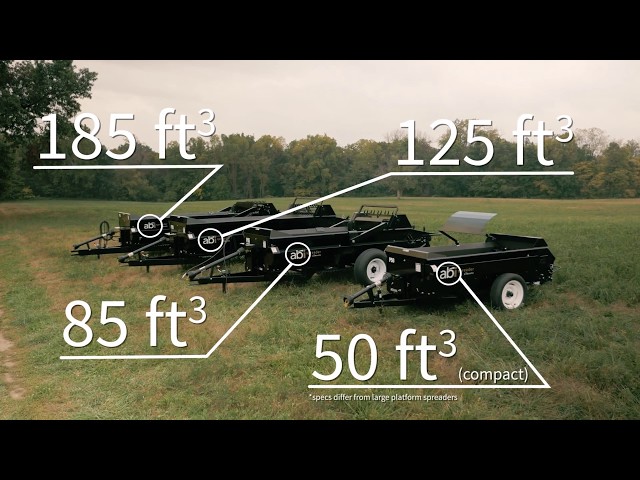

The 85 cu. ft. model is equipped standard with 3 beater bars. Two designed to shred manure and the other designed to spread it evenly. The shredder beaters, with 100 shredding blades, is geared slower than the wide spread beater to maximize shredding power. The spreading beater is expertly designed to further breakdown the manure and evenly distribute it on the ground. The 85 cu. ft. manure spreader has 8 large wide spread paddles. Shredding before spreading and then evenly spreading over a wide swath, exposes more manure surface to sunlight which allows it to dry and decompose far more quickly. Owning an ABI manure spreader that both shreds manure before it spreads and also controls the amount of manure being applied to the ground, enables the horse owner to help maintain an eco-balanced pasture. An eco-balanced pasture can help reduce colic, increase pasture turn efficiency rates, help produce more vigorous grass growth, and reduce odor & flies around the farm.

Advanced PTO Drive System

Unlike many other spreaders, the ABI Manure Spreader provides constant power to the apron chain and beater bars via an advanced PTO drive system. This system utilizes durable chain instead of a belt that wears out over time. Belts slip minimizing power to the beater bars and apron chain and performance diminishes with time. With the ABI Classic PTO Manure Spreader, you are assured maximum power for the heaviest of loads even on soft pastures and slick wintery weather. The entire system is driven by the tractor’s PTO, unlike a ground driven spreader, the spreader wheels are free spinning. The PTO shaft is included.

ABI spreaders are fully-welded with COR-TEN steel to be tank-tough through and through. Our extremely thick COR-TEN steel provides tremendous longevity without the ridiculous expense of stainless steel. So yes, our spreaders aren’t shiny like your kitchen appliances for good reason: stainless steel is not as structurally sound as COR-TEN. Below we have detailed out why our spreaders are built to outlast the barn; and the competition.

Corrosion-Resistant Steel

We start with extremely thick 10 gauge corrosion-resistant COR-TEN steel construction. Unlike most spreaders, the Classic Spreader is a longterm “one-time” investment which has a fully welded box frame, using thicker steel, for worry-free durability. COR-TEN steel may be exposed to the elements, even unfinished, and rust will not perforate it for decades. With COR-TEN steel, you get the longevity and strength required to build a world-class spreader, without the unneeded additional expense and structural weakness of stainless steel.

Protective Body Liner

The inside of the spreader body is coated with a Coal-Tar-Epoxy liner. The Coal-Tar-Epoxy liner adds an industrial seal to protect from the severe corrosive effects of urine filled manure. Coal-Tar-Epoxies are commonly used to line underground sewage tanks and pipelines, and even protect the hulls of barges in salt water.

Lifetime Poly-Lumber Flooring

The bottom flooring is constructed of extremely thick tongue-and-groove polyvinyl lumber that will never rot, rust, or need replacing. Even better yet, the tongue-and-groove construction prohibits the individual poly-boards from warping, preventing excessive wear or damage to the apron web. This is a premium maintenance free flooring that will last and comes standard with a limited lifetime warranty.

Superior-Quality Craftsmanship & Components

Built in Lancaster Pennsylvania, by highly skilled craftsman with decades of spreader building experience, these spreaders are crafted for daily farm-use-conditions and made of the most durable components we know of. Materials such as grade-5 bolts, greaseable bearings, oil-impregnated bronze bushings, heavy-duty size 60 roller chain (nearly 2.54cm wide), T-Rod apron chain, and hardened sprockets ensure longevity. You can judge a spreaders materials and components quality by its overall unit weight, the heavier the better. The ABI spreader weighs nearly 1/3 more than equivalently sized competitors spreaders. Now that is tangible quality you can feel!

Rust-Oleum Paint

All steel components are sand-blasted before painting to prime for perfect adhesion. A special Rust-Oleum “Stops-Rust” black gloss paint, which has a long history of preventing rust on steel in acidic environments, is then applied. Unlike powder-coating, this paint is easy to repair and touch-up and moisture cannot get behind it which eliminates the possibility of rust forming under the finish layer.

Reviews

There are no reviews yet